The School of Medicine’s (WUSM) Facilities Management Department has been involved in two recent efforts at the Central Institute for the Deaf (CID) to optimize the operation of the space conditioning equipment at the school and research buildings in order to save energy and lower operating costs. The Facilities Management Department has operated and maintained the CID’s facilities since 2003.

The Facilities Management Department worked to fully integrate a heat exchanger that can be used as an alternate to the on-site hot water boiler to produce hot water for space conditioning. Konstantin Oleynichenko, Facilities Tech for the building, began by tracing the piping to and from the heat exchanger and boiler along with the various valves and controls in place in order to understand how the system could be operated. He contacted Carl Thomas, Building Automation Controls Tech, who began tracing the controls programming sequences. Carl and Konstantin, pictured above, have made changes that will lead to improvements that will give the CID buildings: 1) greater flexibility due to the alternate heating option, and 2) lower operating cost through more frequent use of the heat exchanger. The heat exchanger’s energy source is steam from the campus boiler plant, which is in turn fueled by natural gas from an account that has a significantly lower unit cost for natural gas.

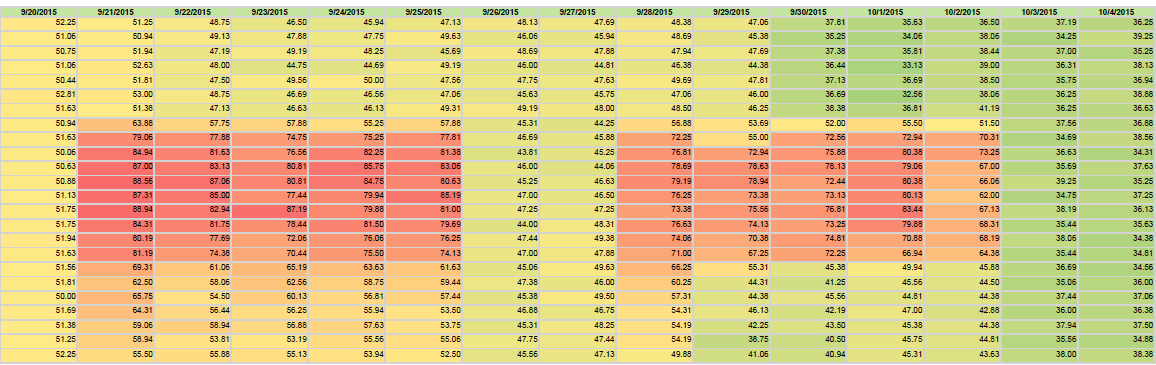

The other effort was a multi-building retro-commissioning project that included the CID school and research buildings. An energy study and subsequent project composed of low capital cost modifications, such as programming occupied and unoccupied airflow sequences and fixing leaking control valves to reduce annual energy costs. The graphic below shows a color coded visualization of the electric usage here by hour of the day (y axis) before and after the unoccupied airflow sequences was implemented within the building control system. After the change, the evening hours and weekends are clearly lower than before the change (green values are low, yellow are mid-range, and red are high).

Both efforts show that optimizing and upgrading controls and controllable equipment can be implemented with quick paybacks on the investment.

Both efforts show that optimizing and upgrading controls and controllable equipment can be implemented with quick paybacks on the investment.